KBR’s Integral Role in Artemis I

The Beginning of Humanity’s Triumphant Return to the Moon

Going down in history as humanity’s triumphant return to the Moon, NASA’s Artemis program and its first mission is just the beginning of the next era of human exploration.

Launched late last year, Artemis I was NASA’s first integrated test of its deep space exploration systems. These include the Orion spacecraft and heavy-lift Space Launch System (SLS) rocket, the specialized ground systems at the NASA Kennedy Space Center (KSC) launch site, and the vital crew and flight control team training systems in the Mission Control Center (MCC) at NASA Johnson Space Center (JSC).

“If you want to send a lot of things over long distances – and humans need a lot of things: air, water, shelter – you’re going to need a big rocket,” Todd May said, KBR’s Senior Vice President of Science and Space. “With the SLS, the U.S. has built the capability to take humankind further than we’ve ever been, and this time to stay.”

This flight test was purposefully uncrewed to assess key components for safety and viability. Crewed missions are planned to occur in 2024. Before that happens, KBR, a long-time NASA partner, and the rest of the space community must ensure the promise of this new endeavor, step by step.

Mission Planning and Launch Operations

At KSC, KBR supported NASA with launch infrastructure activities, computer-aided design models and drawings, as well as analysis packages to NASA and its partners. KBR engineers assisted with materials selection, constructability, and maintainability for all parts of the launch infrastructure design.

These critical tasks included transforming the space shuttle-era processing facility from the precursor moon mission, Apollo, to handle the SLS and its modern needs. As a part of this work, KBR aided the construction of a new Mobile Launcher (ML) with umbilicals – large cables that act as life support. KBR also helped build vehicle access stands for use when the ML is in the Vehicle Assembly Building.

In the lead-up to launch, KBR employees working for both NASA’s Integrated Mission Operations Contract II (IMOC II) and Mission Systems Operations Control (MSOC) supported mission planning by verifying flight requirements; working with engineering, flight and ground system software developers; and developing and verifying procedures and flight rules for real-time support.

The team of instructors and flight controllers underwent extensive certification processes to become mission ready. KBR employees from NASA’s flight production and test office managed schedules, performed integration efforts, and supported testing for communications, flight software, wet dress rehearsals, and pre-launch activities.

The IMOC II and MSOC training and facilities integration teams scheduled an impressive 7,500 events leading up to Artemis I. These allowed NASA to certify personnel and facilities for the flight. KBR also assisted NASA in the Certification of Flight Readiness process, which included significant contributions to the development and implementation of the official certification plan, as well as navigating the challenges that accompanied first-time execution for Artemis.

An important part of Artemis I support is the IMOC II Vehicle Integration and Test Office (VITO), staffed around the clock at KSC starting two days before launch. The VITO team acts as an information hub to assist NASA management in launch progress and countdown, such as monitoring flight status, upcoming milestones, and reporting climate conditions.

As the prime contractor on NASA’s MSOC, KBR configured NASA’s Mission Training Center in advance of launch to support simulations analyzing communication coverage during Artemis lift-off. For the SLS to launch, everything from the weather to the hardware and personnel support must be in exact order or the mission could get scrubbed.

“Once you light the solids, you’re going to go somewhere,” May said. “The hardest part is getting one inch off the ground.”

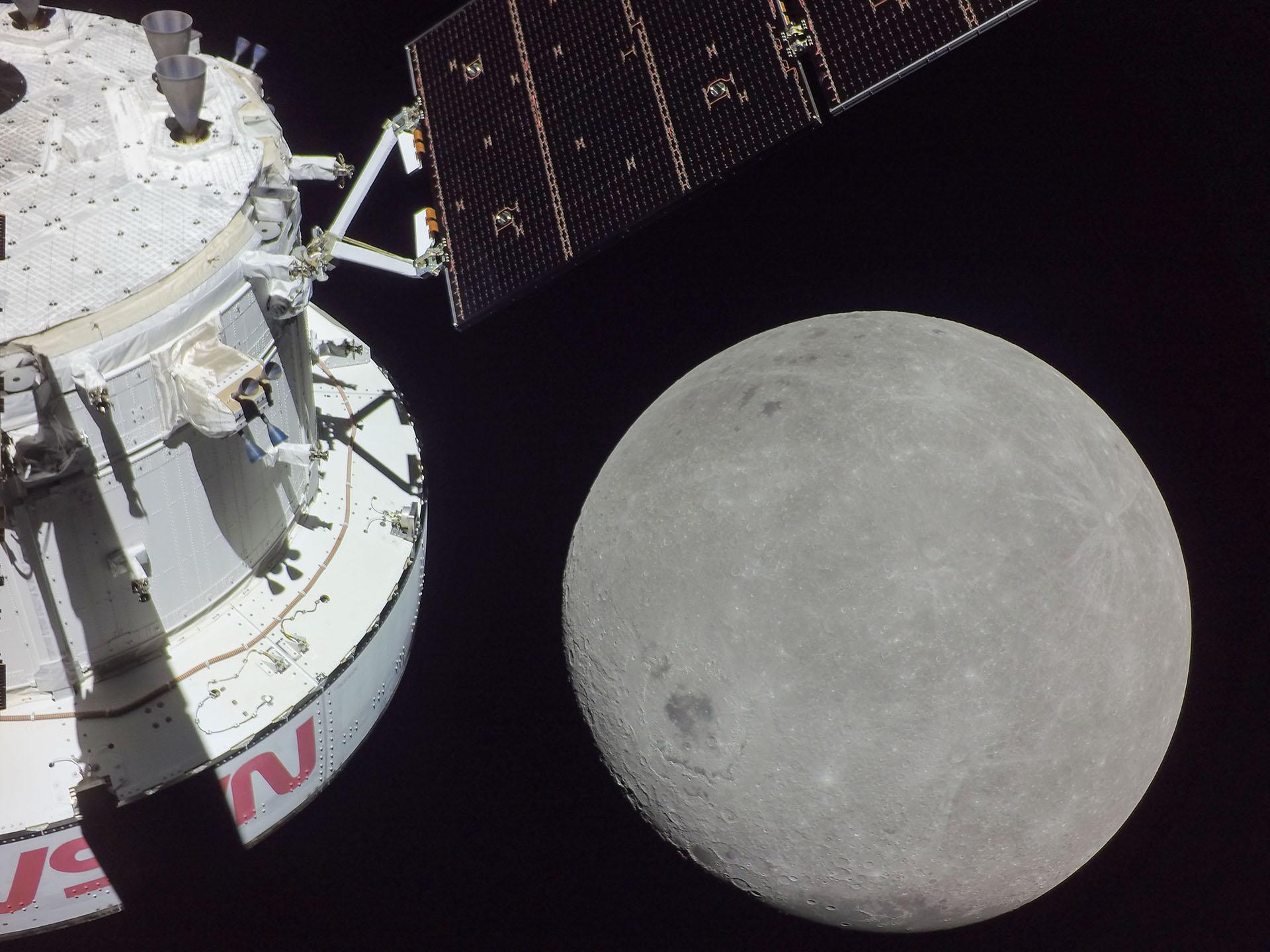

In the early hours of Nov. 16, 2022, NASA’s heavy-lift SLS rocket carrying the uncrewed Orion spacecraft successfully lifted off from Launch Complex 39B in Florida and made history. Lasting 25 days, 10 hours, and 53 minutes, the mission traveled 1.3 million miles at speeds of up to 24,500 mph to reach a distant retrograde orbit around the Moon and return home.

KBR’s IMOC II team provided personnel on the range safety and public entry risk assessment teams to analyze the different parts of the Artemis I vehicle that are shed during its ascent and entry flight phases, the rocket’s lift-off and depart from the Earth’s atmosphere to space. These included elements such as the SLS core stage, solid rocket boosters, and Orion heatshield to make sure they do not land on any foreign or domestic soil, especially populated areas.

SLS Development

KBR helped the NASA SLS team engineer the most powerful rocket to ever fly. As a part of the VITO at NASA Marshall Space Flight Center (MSFC), KBR supported the SLS Block 1 design, analysis, manufacturing, testing and integration for flight. KBR was involved from preliminary design review through certification and provided regular feedback to NASA on design requirements, certification plans, hazard reports, and testing to ensure flight and astronaut safety.

Additionally, KBR experts worked on the design, development, test, and evaluation efforts of the Core Stage (CS), Exploration Upper Stage, and Interim Cryogenic Propulsion Stage. As the world’s tallest rocket stage towering 212 feet, the CS stores critical cryogenic liquid hydrogen and oxygen, as well as the avionics technology needed to control the rocket’s flight. KBR also provided primary design and production support for the vehicle’s most complicated component: the engine section. With miles of cabling and hundreds of sensors, the engine is the lowest portion of the massive CS for NASA’s rocket.

KBR systems engineers from NASA’s Intelligent Systems Research and Development Support Contract at Ames Research Center put untold hours into modeling the operation of the SLS systems. This lengthy process included running simulations with the ground hardware and developing the software interface that vehicle management engineers used to monitor the vehicle parameters during launch.

Flight Operations

KBR flight controllers provided another essential contribution to the Artemis I mission. These experts on IMOC II and MSOC fly the SLS rocket and the Orion spacecraft and have been training for more than two years to support this significant historic milestone.

Orion, which sits atop the SLS, serves as the exploration vehicle to carry future crews to the Moon and beyond. IMOC II personnel served as members of the Day of Launch I-Load Update (DOLILU) team. DOLILU is the process SLS utilizes to minimize air loads – a form of resistance – during launch.

This designated group designs the onboard guidance for the steering commands to help Artemis I achieve a good orbital insertion, or adjustment into orbit, like merging onto a highway.

More than 50 IMOC II and MSOC employees monitored the Artemis I mission, including certified flight controllers staffing a variety of console positions in the MCC and certified instructors offering technical insight as needed. KBR’s flight control team provided support around the clock during the multi-week mission, monitoring vehicle performance and commanding the spacecraft through successful burns and transitions as it journeyed to the farthest point in space reached to date by a human-rated spacecraft.

By operating the vehicle in a deep space environment, KBR and our teammates were able to test Orion’s heat shield and module recovery procedures after reentry, descent and splashdown – the return of the spacecraft into Earth's atmosphere and subsequent water landing. Impressively, KBR’s flight operations teams provided simultaneous real-time operations of all of NASA’s human spaceflight vehicles in the MCC, including both Artemis and the International Space Station.

KBR has been supporting NASA’s simulations and training activities for Artemis for a while. Throughout this time, KBR completed more than 270 vehicle requirements for Orion, such as important upgrades and sustainment activities to the MCC like its ground system infrastructure, mission system engineering and operational applications. At the end of the day, KBR was able to provide a more robust and capable simulator than originally requested, which will prove very useful in Artemis missions to come.

IMOC II employees working in the Rapid Prototype Lab at JSC were also responsible for creating Orion crew displays for various Artemis missions, while other IMOC II teams did configuration management for more than 4,300 documents and published 405 procedures to support the program.

Human Health and Performance

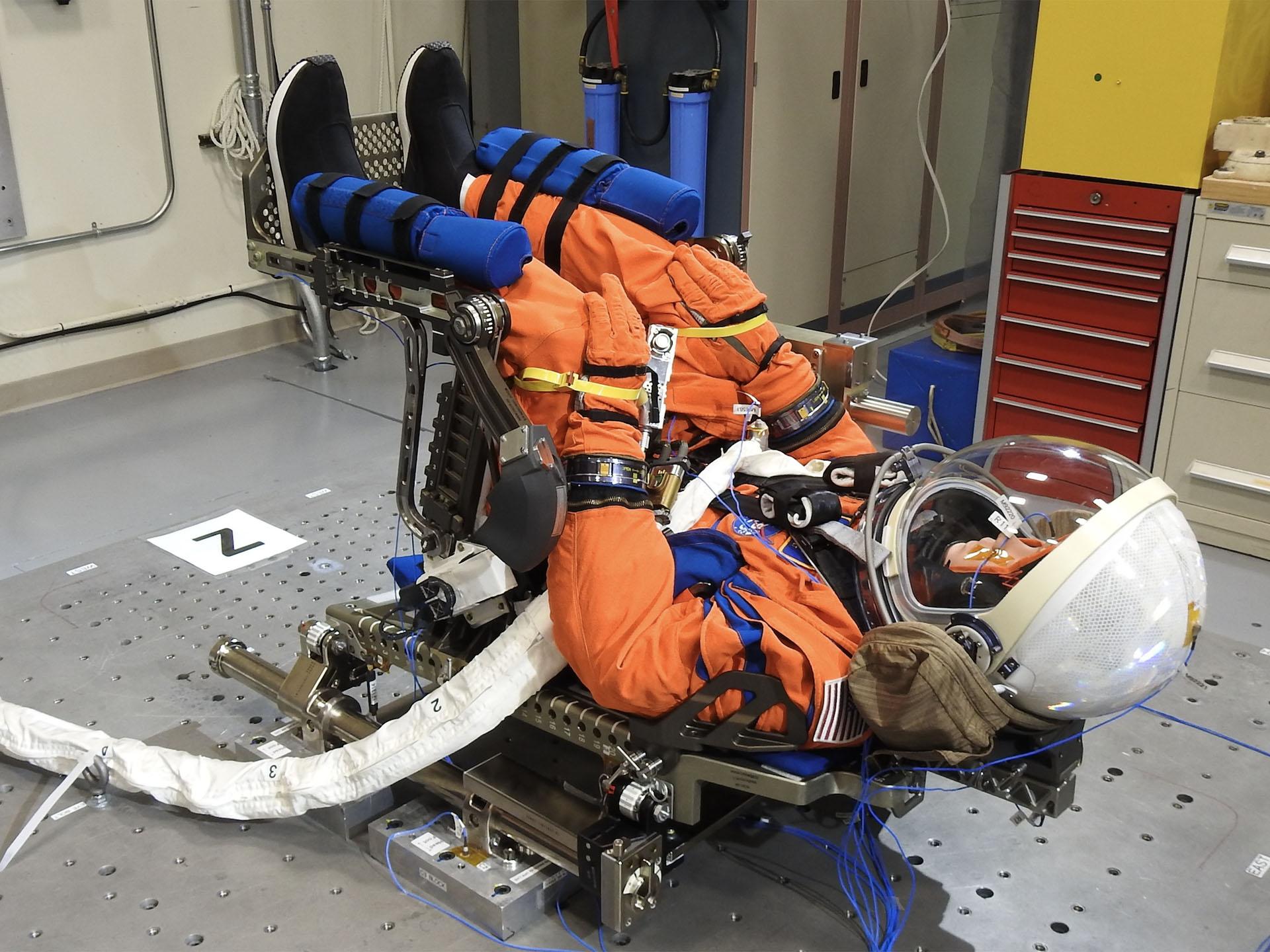

Although Artemis I is an uncrewed flight, KBR’s Human Health and Performance Contract (HHPC) team was still heavily engaged. Leading up to the Artemis I mission, KBR supported NASA through vehicle integration, with a focus on Orion’s verification of human systems requirements. Viewing Artemis I as a dress rehearsal for future crewed flights, KBR helped develop landing and recovery plans, including emergency escape systems, and determined other ways to minimize risk to the crew.

The KBR human factors team completed interactive human-in-the-loop assessments for much of the Orion interior hardware. They did extensive testing to evaluate and inform designs for all aspects of the vehicle-crew interface, which includes crew seats, display panels, and operations of the vehicle hatch to ensure safe performance during both normal flight and emergency scenarios.

The applied injury biomechanics team on HHPC specifically supported the development of the crew seat accelerometer (CSA), used by a manikin onboard Artemis I: “Commander Moonikin Campos.” The CSA is intended to collect data needed to assess acceleration, vibration and other dynamic flight requirements for astronauts on Orion vehicles.

The CSA collected the data needed to assess acceleration, vibration and other dynamic flight requirements for astronauts on Orion vehicles. Once back on Earth, the team processes and analyzes these metrics to guarantee crew safety for upcoming crewed flights.

Additionally, the HHPC space radiation team provided science and engineering support for the development of the Artemis-1 Hybrid Electronic Radiation Assessor (HERA), the primary part of the spacecraft radiation detectors. As many know, without proper protection, space radiation can pose a major threat to the human body.

The HERA system performed flawlessly with an outstanding correlation between modeled projections and real-time measurements. The team also participated in the Matroshka AstroRad Radiation Experiment (MARE), which equipped the onboard mannequins with sensors to track astronaut radiation exposures during future exploration missions.

It’s important to note that during the mission, KBR members of the Space Radiation Analysis Group (SRAG) supplied flight control support from NASA’s MCC in Houston as they normally would in preparation for the next crewed Artemis mission. SRAG works in collaboration with the NOAA Space Weather Prediction Center forecasters and the Goddard Space Flight Center Moon to Mars Office to evaluate operational hardware, tools and procedures.

Payload Engineering and Telemetry

Riding onboard Orion was a technology demonstration called Callisto, a vehicle-connected crew interface payload that includes Amazon's Alexa voice-activated virtual assistant and Webex by Cisco, a video communication and collaboration software tool.

MSOC team members provided engineering support for Callisto and trained the network operations controllers on the necessary tasks to support the increased number of activities during the mission. As a part of this project, KBR provided telemetry data to the Callisto operations team and the NASA Artemis Real-time Orbit Website visualization tool. The data was used for an Alexa skill allowing virtual crew members in the Payload Operations Center at JSC to ask questions about the mission in real time. For example, throughout the 25 days tester could inquire, “Alexa, how close is Orion to the Moon?” and you’d get an answer based on the telemetry KBR supplied.

Moreover, NASA used this telemetry data to produce some of the informational graphic overlays seen in the media. Not only is KBR enabling Artemis’ flight hardware and software, but we are also supporting NASA’s publicity efforts to show off the mission around the world.

KBR teams from multiple contracts put a lot of hard work into every aspect of the Artemis I mission and are key contributors to this important and exciting program.

On the morning of Sunday, Dec. 11, 2022, NASA’s Orion spacecraft safely splashed down in the Pacific Ocean after a record-breaking mission that was deemed highly successful, completing the Artemis I flight test.

One might ask: Why did it take so long to go back to the Moon?

Simply put, “Space is hard,” May said. Fortunately, “In these challenging times, space is something that brings humans together. This is a uniting moment for us all.”

As a part of the modern moon program, NASA and its partners are working together to land the first woman and person of color on the moon, to create an orbiting outpost, build a long-term presence for science and exploration, and, most excitedly, to form the foundation for a future trip to Mars. We invite you to join us in the coming months – and years – as we continue to chronicle KBR’s ongoing role in one of the greatest missions of our lifetime.

Congratulations to NASA for the success of Artemis I. KBR is proud to be along for the ride!