Carrying the legacy: KBRwyle continues to make safer armored vehicles for soldiers

Two years ago in Afghanistan, soldiers of the Apache troop of the 75th Cavalry Regiment were collecting intelligence and clearing locations previously used to launch rockets and mortars at Bagram Airfield. As they patrolled the familiar area in their Mine Resistant Ambush Protected (MRAP) vehicle, they took a right turn and their world exploded around them.

"We got tagged with an IED [improvised explosive device]," Pfc. Jeremiah Hutson, the MRAP driver, said.

The MRAP deflected the majority of the blast due to its V-shaped hull, protecting the soldiers from serious injury.

"Two of my best friends that are here on deployment were sitting right over the explosion," Hutson said. "So, you know, not only did it save their lives, it saved the other guys' lives as well."

Explosive Ordnance Disposal Soldiers conducted an analysis of the incident and determined that the soldiers' injuries would have been much more severe if they had been in another type of vehicle.

KBRwyle has proudly worked with the MRAP Army Project Office (APO) for the past eight years to ensure soldiers, like Hutson and his friends, come home to their families.

MRAPs are armored fighting vehicles designed to combat IEDs, roadside bombs and ambushes, and are currently used by all U.S. armed services. Soldiers have relied on MRAPs for the last eight years of combat operations. During the first years of conflict in the Iraq war, IED attacks caused the majority of U.S. casualties, making the MRAP program a top priority for the Department of Defense.

From the armored vehicles' first days on the front lines, KBRwyle has provided a wide array of logistics product support to help the Army maintain the operational relevancy of the MRAP vehicle fleet.

"KBRwyle supports the warfighter," said John Mikelaitis, KBRwyle program manager, land vehicles, sustainment engineering division. "We perform every task assigned to us by our customer knowing it will impact the warfighter's daily mission. We fully understand that the outcome of our efforts will have a direct effect on each woman and man using or maintaining a MRAP vehicle."

KBRwyle lead analyst, Sarah Oderkirk, based in Sterling Heights, Michigan, provides Care of Supplies in Storage support to MRAP vehicles.

Now and then: KBRwyle's work over the years

Early in KBRwyle's service to the MRAP APO at Tank Automotive Command (TACOM), the KBRwyle team was tasked with performing Reliability Centered Maintenance (RCM) on a several variants of the MRAP. These different variants included the Cougar, RG-33, Buffalo, MaxxPro, Caiman, and M-ATV. Critical to ensure its success, KBRwyle needed to overcome the challenges of sparse data availability due to the rapid production and fielding of the vehicles in theatre.

Through diligence and perseverance, KBRWyle analysts and engineers provided recommended improvements to reduce maintenance turnaround times, increasing availability of the vehicles for Soldiers, Marines and Special Operation Forces. KBRwyle also recommended a maintenance program that streamlined maintenance procedures by eliminating unnecessary tasks, essentially making maintenance more efficient, effective and reliable for the men and women on the frontlines.

Through KBRwyle's efforts and working closely with TACOM, the team provided the MRAP program millions of dollars in cost avoidance and significantly reduced the man-hours required to perform Preventative Maintenance Checks and Services (PMCS) tasks.

According to Steve Anderson, Army M-ATV Integrated Logistics Support Manager (ILSM), the maintenance improvements played a key role in saving countless lives.

"Since the inception of the MRAP vehicle, the top priority of the Department of Defense was to ensure the safety to our troops during our country's war on terrorism," said Anderson.

"KBRwyle's support played a key role in significantly reducing casualties to the warfighter during these volatile times."

Today, KBRwyle's role in supporting the MRAP has grown. As RCM becomes a sustainment effort, the company's analysts continue to support the warfighter by providing services for Care of Supplies in Storage (COSIS). The KBRwyle team identifies emerging failure modes discovered from data received from Fort Bliss Texas, Space and Naval Warfare Systems Command (SPAWAR) in Charleston, South Carolina and in Red River Army Depot (RRAD), Texas. With the foundation of experience, KBRwyle's teams across the country lend their engineering and logistic expertise to ensure the Army's armored vehicles are safe and easy to maintain in support of the nation's fight against terrorism.

Pictured left to right: KBRwyle employees Dale Paul, Blake McIntosh, Steven Weaver, based in New Boston, Texas, Red River Army Depot (RRAD), provide COSIS support to MRAP vehicles, including the MaxxPro (pictured).

KBRwyle's Teams

The KBRwyle COSIS team based in Sterling Heights, Michigan, and RRAD Texas support the M-ATV and MaxxPro ILSM. This team reports COSIS vehicle status, readiness, parts status, trends, and action items through quad charts, bar graphs and monthly reports.

KBRwyle's engineers and analysts in Jacksonville, Florida, provide Reliability, Availability and Maintainability (RAM) analyses for track and suspension, hull, frame, body and cab, and armor. This team develops Design Failure Modes and Effects Analysis and preliminary design review artifacts, and constructs reliability prediction approaches and timelines for combat vehicle prototypes.

Technical writers, teamed with MRAP APO, are developing instructions for removing and replacing the floor of the M-ATV and camo painting the M-ATV and MaxxPro. The team is also developing instructions on how to repair the Remote Weapons Systems and Objective Gunners Protection Kit seals to prevent water intrusion within the vehicles' cabs.

The team in Sterling Heights, Michigan, provides logistics and engineering support to several programs. Highly-qualified engineers work with the U.S. Army's Tank Automotive Research Development and Engineering Center (TARDEC). These engineers perform tasks focused on Ground Vehicle Power and Mobility technologies research and development. These tasks include integrated systems engineering and testing in TARDEC's Propulsion Laboratory; evaluation of system level performance; analysis to identify corrective action and re-engineering for problems identified in the field or during testing; and research into novel design initiatives to increase efficiency and gain capability for vehicle power systems.

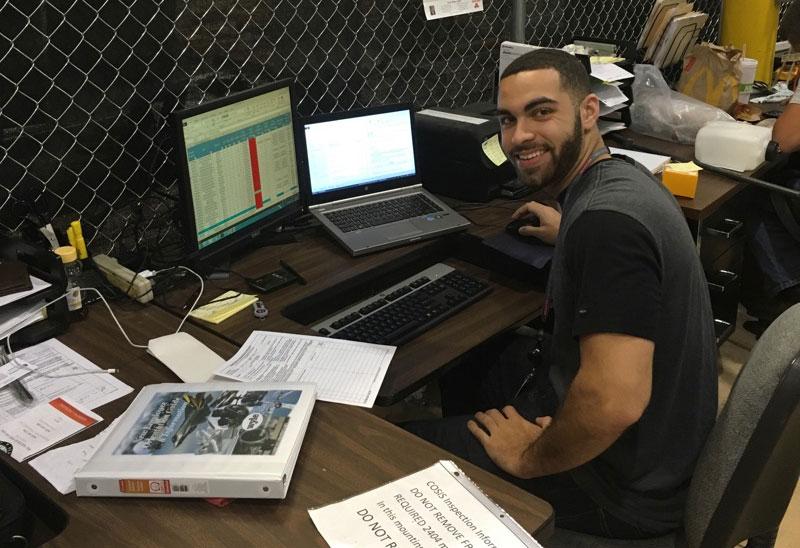

KBRwyle analyst, Devin Anderson, based in Charleston, South Carolina, provides Care of Supplies in Storage (COSIS) support to the MRAP All-Terrain Vehicle.

KBRwyle engineers also pursue new solutions and initiatives for fielded systems, such as applying Condition Based Overhaul methodologies in Army depots to provide life cycle cost reduction and design changes to improve durability. These engineers provide technical expertise regarding powertrain performance to Scientific and Technology (S&T) and other introductory programs. Additionally, the team provides direct logistics support to the M-ATV and MaxxPro programs and has assisted the ILS Center in the validation of the MaxxPro technical manuals developed by Navistar.

With new tasking on the horizon, KBRwyle will continue to deliver the highest degree of service supporting the warfighter. According to the Army, "MRAPs have saved the lives of thousands of U.S. soldiers and coalition partners. The MRAP fleet is an invaluable legacy—and as it is brought home for modernization, acquisition professionals become stewards of that legacy."

KBRwyle will continue to be a part of this legacy as the company supports MRAPs throughout their life cycles, ensuring America's men and women on the frontlines are equipped with the most capable and safest vehicles.

Photos by: Robin Putrycus