KBR's Australian Infrastructure Business Achieves 365 Days of Laser Scanning

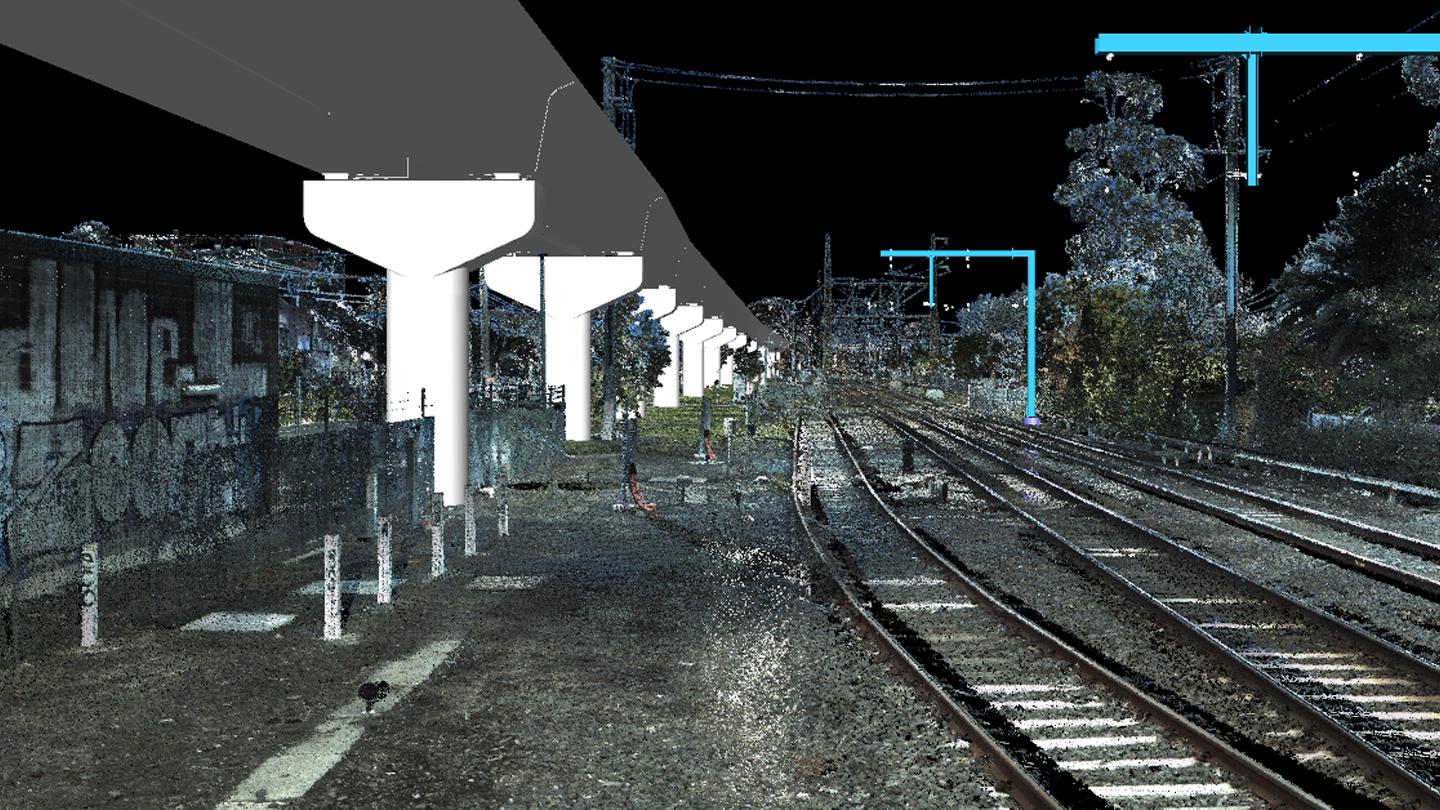

The application of Digital Survey in the form of Terrestrial Laser Scanning (TLS) continues to enhance the way KBR’s Infrastructure Services Australia business delivers brownfield transport and water infrastructure projects. Eight years in the making, the team recently achieved 365 days of capturing field data on site.

Commencing in Australia in early 2012, KBR’s digital scanning capabilities have continued to evolve year on year and offer far reaching benefits, including significant safety improvements for field teams by eliminating or reducing the need for working at heights, in confined spaces and on elevated working platforms. The ability to capture data from a safe distance also reduces project costs by eliminating the need for traffic control, facility, road or rail closures and minimizes disruption to the public.

The team is also nearing its 200th project, consisting of a range of disciplines including rail track, tunnels and viaducts, storm water drains and sewers, water and wastewater treatment plants, petrochemical and gas plants. The results are used for all stages of design, from feasibility through to as-constructed. TLS has not been restricted to design projects, with an increase in recent years with the implementation on condition assessment and dilapidation surveys. Other non-traditional applications have included surveying koala tree habitats and scanning the internals of a train drivers cab for a virtual reality application.

KBR’s capabilities are not restricted to the capture and processing of data, they also include the use of data for design, feature extraction, visualizations, animations and using 3D Point Cloud models for other applications including virtual and augmented reality. The varying formats, applications and tools provide the ability to seamlessly design and construct an optimized solution.

The expansion of Digital Survey into the Australian region was made possible by the support of the As-Built Service team in Birmingham, Alabama, USA, whom have been delivering TLS services to Global clients since the late 1990’s. The sharing of knowledge and skills over the years has shown KBR’s commitment to a global digital technology focused approach.

The models can also be used to enhance constructability through HAZOP and CHAIR workshops, and for briefing stakeholders and suppliers to plan remediation works, calculate the quantity and location of scaffold, the amount of equipment and materials needed and to identify laydown areas and exclusion zones. This data enables increased collaboration and can be reused or repurposed by the client for added value.

In recent times, TLS has become invaluable with the onset of COVID-19 limiting access to projects sites, enabling teams to practice social distancing and collaborate remotely while still having full access to an asset or site with click of a button. The KBR project team has received positive feedback and praise on our employees’ ability to deliver projects from their homes without sacrificing the quality and detail of the deliverables, whilst having no impact to the project budget or delivery schedule.